Flat Beds, Tilting Tables & Vertical Moulds

Flat Beds

A.K Bryan can manufacture steel beds of any size with architectural standard finish to faces. As shown, with shuttering window former's etc to suit your required panel thickness.

Large Flat Beds - something simple and durable.

Using our shuttering and magnet system, this system can produce various forms of concrete. Shuttering made to your desired dimensions allows flexibility in production form work.

Using our shuttering and magnet system, this system can produce various forms of concrete. Shuttering made to your desired dimensions allows flexibility in production form work.

Tilting Tables

|

Our Tilting tables are designed for the forming of large area concrete products. Usually to create wall or floor panels, when used with our magnetic or bolt on shuttering systems.

The surface of the steel plate is ultra flat and guarantees a high-quality concrete surface. Various face finishes are available upon request. By the method of sand blasting. Using our latest CAD Design/Engineering software, we can provide models of how the mould will work. Including any calculations if required. Electronically controlled hydraulic systems are used for the lift and lowering of the bed. |

More Tilting Tables

Here we have 3, yes 3!! 4.5m wide x 10m long tables. These hydraulically assisted tilting tables are independantly controlled by there own control unit.

Large Vertical Moulds

|

Once designed using our latest CAD Engineering Software we can provide a structural calculation and FEA analysis to ensure that the mould is strong enough to withstand any deflection or deformations that may exceed the given tolerances.

This Vertical Mould was 12m x 3.7m. The opening side was hydraulically assisted. The fixed side consisted of the walkway to aid setting up, pouring and the demoulding process. Our vertical moulds are robustly constructed and designed for ease of use. |

This is a double cast Vertical Mould. Each side consists of fixed end plates with pre-arranged holes to mount features as per customer requirements.

To help the demoulding process, each side is hydraulically assisted, with independent controls easily accessible from ground level. The walkway between each side is accessed via a bolt on ladder. (Removed for transport). Tie brackets top and bottom help prevent any expansion from pressures created.

To help the demoulding process, each side is hydraulically assisted, with independent controls easily accessible from ground level. The walkway between each side is accessed via a bolt on ladder. (Removed for transport). Tie brackets top and bottom help prevent any expansion from pressures created.

Small Vertical Mould

Open Vertical Mould

Open Vertical Mould

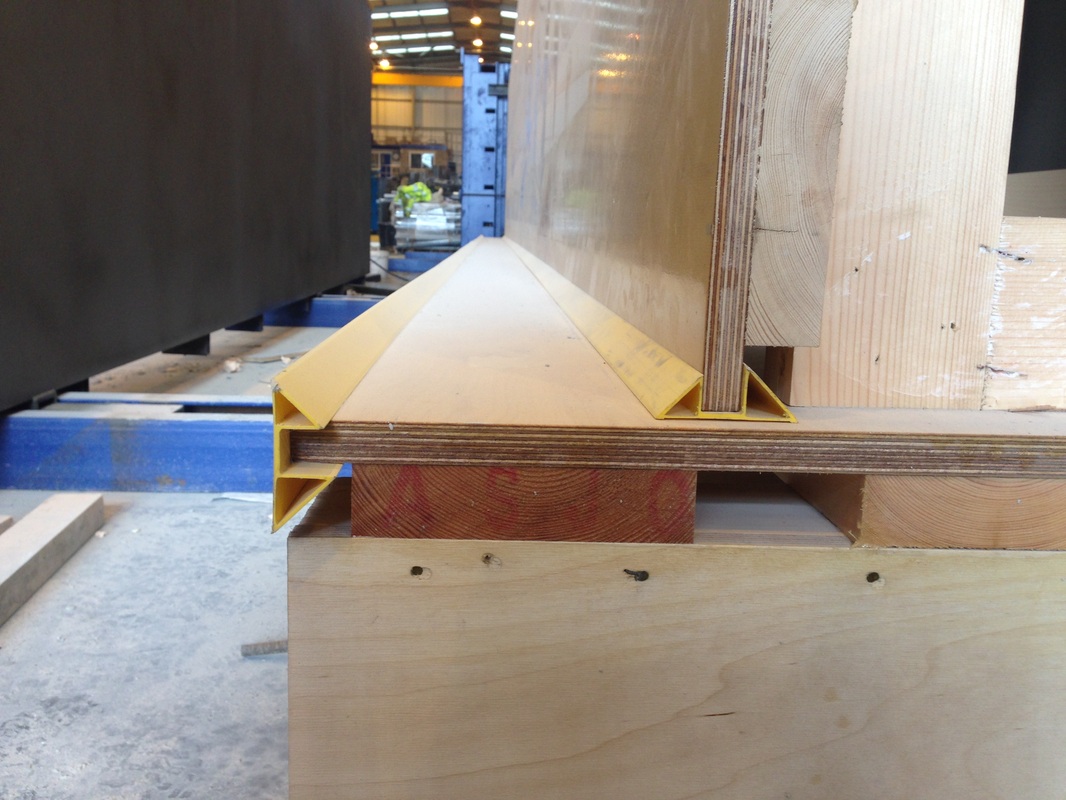

This smaller vertical mould was manufactured to cast flat wall panels. But in this case our customer then retro-fitted a timber internal carcass to form a spandrel unit. Our plastic chamfer was used to chamfer all long edges.