What's New Here At A.K Bryan..?

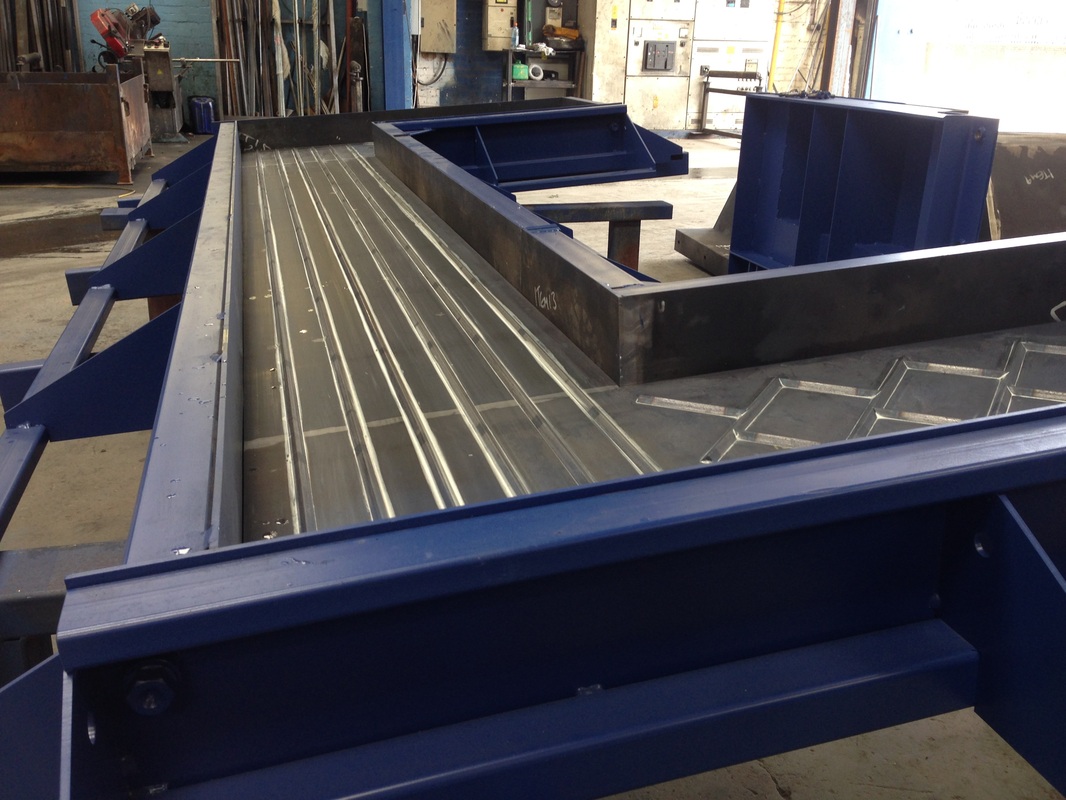

Latest - 14m x 4m Hydraulically Assisted Tilting Table

Our latest Tilting Table was designed and manufactured to our customers requirements. A large 14000mm x 4000mm casting face.

An electric control panel provided with all necessary safety certificates to run hydraulics moving the table up/down between casting and stripping.

Using our flat bed, we are able to offer Shuttering solutions to create your desired project.

We can provide a magnetic or bolt on shutter, manufactured to your needs.

With calculations provided, our rebust Tilting Table will be used for many many years.

More photos can be found here...

For more information about our Tilting Tables, please contact us on 01773 602606.

An electric control panel provided with all necessary safety certificates to run hydraulics moving the table up/down between casting and stripping.

Using our flat bed, we are able to offer Shuttering solutions to create your desired project.

We can provide a magnetic or bolt on shutter, manufactured to your needs.

With calculations provided, our rebust Tilting Table will be used for many many years.

More photos can be found here...

For more information about our Tilting Tables, please contact us on 01773 602606.

NEW 20m x 1.5m Steel Beam Mould

This large mould was designed and manufactured in a fast turnaround! Check out more details by clicking here.

NEW Adjustable Culvert System

|

|

Our new fully adjustable Culvert System.

Culverts, lift shafts and wall units can be produced using this system. Sizes and number of internal core assemblies to suit all customers specifications are available. A solid steel base supports interchangeable sides for varying dimensions you may require. Hydraulic rams aid the de-moulding process by reducing the inner core size to allow the unit to be then lifted out. Adjustable soffits to create different depths of units. <<< Click the video to see more.. Check out more of our culvert moulds |

Concrete Skip Pourer

|

|

Our new multi-purpose upright skip with a large opening for easy concrete pouring. Our skip is sprung loaded, helping the opening and closing of the pour more efficiently. Accurate pours reduces waste from spillages.

|

Large Duct Moulds

Duct moulds are used to create spaces. This particular duct mould was a 3.7m high cell (Total Weight 8000kgs). Once cast a quantity of units, they are put together to create a row of individual cells.

This steel duct mould was made to ensure ease of use. So we made retractable sides on a wheel system. Tie bars to keep the correct stone width required and boltable end plates for more efficient setting up times. Moveable platforms to allow access to all sides of the mould were also manufactured for this job. In the pictures below, you will see that they were made the correct height for suitable working and ensuring they met all safety standards. We have manufactured many duct moulds in the past, varying in size, with additional extras including bobbings and blockouts to create spaces for taps and waste pipes etc. Half Column - Building cladding - Chelsea Creek, London.

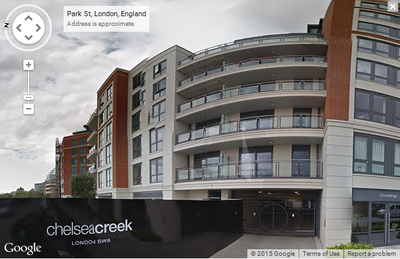

Evans Precast Concrete asked us to design and develop a mould for their Chelsea Creek Project in London.

Here are picture of the units once cast, and then of them in place fitted to the building. Evans Precast has supplied over 500 units of cladding panels, Spanish dolomite, spandrels and facetted fin units. Most of which have came out of our moulds. Sheet metal laser cutting!

Here at AKB, we now have the capabilities of laser profile cutting. Our huge 4.2mx2.2m flat bed can process larger sheets many companies can't. Our largest sheet used so far is 4180mm x 2010mm. We can produce bespoke lifting brackets and any size washer you may require... Click Here For More Details... |

|

|

Vertically Cast Round Columns.

Our latest columns were 4m long and 350mm in diameter. They featured chamfered tops with height adjustable soffits. The mould skins were blasted to eliminate any shiny surface which would show up on the stone. Blasting the units also gave the skins a texture. This texture can be various depending upon clients requirements. |

|

|

Hydraulic assisted steel moulds to create a Drainage System for Headwall.

The two sides powered by the hydraulic rams aided the de-moulding process. Breaking the seal of cast concrete sometimes proves to be difficult. Using this method makes the process easier and safer, as you control each ram from behind the mould. |

|

|

|

A Tapered Arch. This arch measured approx 6m x 2.2m across the span. With a radius of 3.1m outside and 2.9m inside. The end plates are adjustable to set the desired tapered end and size of the unit. The outer and larger side of the two was fixed to wheels. The mould easily opened up allowing fitment of new chamfer or new soffits if needed, as well as part of the de-moulding process.

|

|